中文(中国)

中文(中国)

- English

- 中文(中国)

- Русский

- 한국어

- עִבְרִית

中文(中国)

中文(中国)

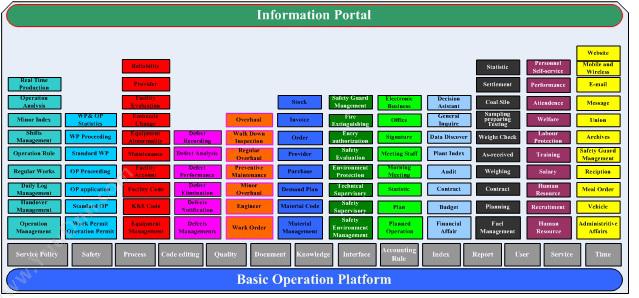

一、MIS系统功能介绍

1.MIS Overview

1.1 Functions

MIS系统以企业资源计划为指导,以电厂资金流、信息流、工作流、物流的统一为目标,将发电企业的全部信息整合在一个统一的平台上,建立一个以企业设备资产管理为基础具有ERP功能现代电厂生产管理系统。

The Management Information System (MIS) is guided by the principle of planning a corporation’s resources, and aims to unify the flow of funds, information, work and materials in a power station. It puts all the information on the same platform, establishing a modern plant production management system that is based on equipment and logistics management and with ERP function.

1.2Advantages:

1.2.1Improving competitiveness

Full application of MIS shortens time spent on solving problems, reduces operating costs, and increases efficiency.

1.2.2Standardized operating flow and knowledge sharing

通过MIS系统将企业内的运行、维护、规划/计划、财务、物资、工程管理、文档资料等信息以设备的运行、维修为主线形成标准工作流程,将实现事前计划、事中控制、事后报告与分析一套完整规范的工作方式,同时实现经验积累与知识共享。

MIS creates standardized working processes based on equipment operation and maintenance involving information related to operation, maintenance, planning, finance, logistics, project management, and files. A complete and standardized working mode involving prior planning, control, and post-event report and analysis. It performs experience accumulation and knowledge sharing.

1.2.3Value realization

降低维护费用20-60% reduces maintenance costs by 20-60%

1.2.4Assistance in realization of commercial targets

提高总体效率 improves general efficiency

1.3Features

1.3.1MIS collates power generation safety information and classifies and reports it to provide base data for overall analysis and economic indices.

1.3.2It analyzes, classifies and calculates information relating to plant management and technological upgrades for improving equipment completeness. It shortens times required for equipment repairing and overhaul and reduces maintenance costs, improving unit availability. It enhances evaluation of maintenance personnel, thus increasing the plant production quality level.

1.3.3It enhances planning management and improves prediction skills. It uses advanced models and methods and provides optimized solutions to assist management with decision-making.

1.3.4 It presents information about finance, human resources, payroll, material supply, fuel management and employees training, allowing users to understand state of operations, optimize management, and improve working and economic efficiency.

1.3.5It provides modern methods for handling office business. It takes advantage of computers and the Internet for information service provision and assisting in production management. It has information management to promote multiple operations.

1.3.6It incorporates on-line production information from supervisory system of existing units into MIS and provides unit operation data and partial statistical data to perfect the production statistical system and to automatically produce the statistical data reports.

1.3.7It provides integrated information services and partial assistant predication and decision making services for senior management.

二MIS系统的维护、培训及售后服务

2.Maintenance, Training and After-sale Services

2.1Maintenance

2.1.1Regarding system establishment, regulatory systems and evaluation standards should be drawn up which benefit the stable operation of MIS.

2.1.2Scheduled maintenance should regularly be carried on the computer network and computer devices.

2.1.3Rules and processes which fail to comply with MIS requirements should be re-arranged or modified.

2.1.4Personnel associated with MIS must be trained periodically or when necessary.

2.1.5Strict entry authorization should be established. Effective technical procedures and management measures should be applied to prevent the system from being invaded and prevent data from being accessed illegally.

2.1.6An effective data backup system should be drawn up and periodically inspected for safety.

2.1.7Professional computer management personnel should be assigned to the system, and they should be trained and evaluated individually.

2.1.8Fault descriptions of the software and analytical conclusions should be carried out.

2.1.9Software engineers should be contacted for remote assistance if necessary.

2.2Training

Administrator training: training for system administrators covers professional maintenance knowledge of MIS and fault handling.

2.3After-sale services

2.3.1The warranty period of software system is one year after it passes the overall acceptance. There is free technical support during the warrranty period.

2.3.2.When a software fault occurs, the users need to understand the nature of the fault and record it in the Applications Failure Log as well as taking fault isolation and characterization measures. Solutions are provided to users for free within the warranty period.

2.3.3The engineer, after arriving on Site, should analyze the fault(s) on the basis of the Applications Failure Logs provided by the maintenance personnel and select appropriate service strategies according to the fault class. Confirmation should be carried out after the fault is repaired and the problem tracked regularly.

3.Equipment and spare parts

3.1.MIS covers all of the main and auxiliary equipment in the plant. As such, it provides management services relating to basic information entry function, equipment operation information, equipment maintenance processes and equipment spare parts.

3.2The operation of MIS system relies on hardware equipment and software. The hardware includes: central exchanger, secondary exchanger, data base server, backup server, WEB application server, users end, printer, scanner, and network equipment. Software includes: MIS application software, database software, operation system software, Microsoft office suite and backup software.

3.3Spare part management block in MIS system can manage the spare parts of all equipment in power plant on registration, status and storage of spare parts. This system provides solely on information management function to spare parts, and the spare parts list is input into the system by power plant personnel taking the practical condition of power plant as basis.